Tournage de haute précision ±0,005 mm

PCNC Turning Parts est réputé pour sa technologie de tournage de haute précision exceptionnelle, capable d'atteindre des tolérances serrées de ±0,005 mm. Cette précision assure la stabilité et la cohérence des composants dans la fabrication haut de gamme, en particulier dans les industries avec des exigences dimensionnelles et d'ajustement strictes, telles que l'aérospatiale, les dispositifs médicaux et l'électronique de précision. Cette haute précision améliore non seulement les performances du produit, mais réduit également efficacement les erreurs et les rebuts lors de l'assemblage ultérieur.

Spécifications du produit

| Nom du paramètre |

Valeur |

| Tolérance |

±0,005 mm |

| Méthode de traitement |

Tournage CNC |

| Options de matériaux |

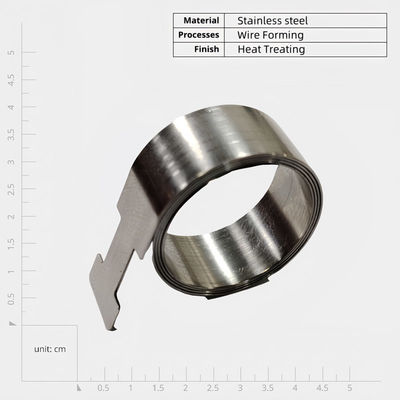

Alliage d'aluminium, acier inoxydable, laiton, etc. |

| Rugosité de surface |

Ra0.8 - Ra1.6 |

| Plage de diamètre de traitement |

φ1mm - φ300mm |

| Plage de longueur de traitement |

≤ 500mm |

| Commande minimum |

1 pièce |

| Vitesse de traitement |

Tournage de précision à grande vitesse |

| Méthode d'inspection |

Mesure de coordonnées, projection |

| Applications |

Aviation, Automobile, Électronique, Médical |

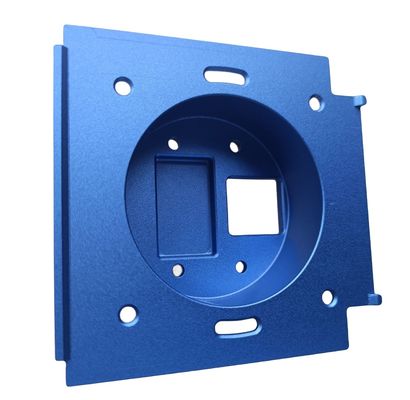

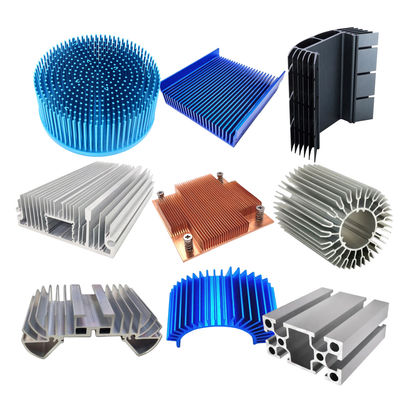

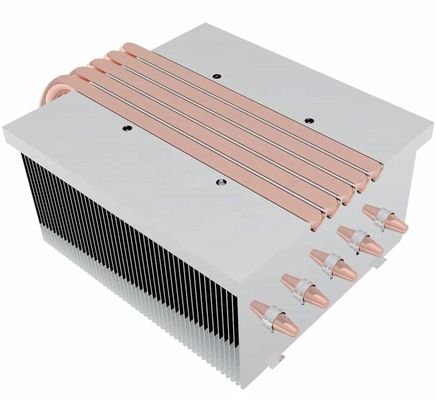

Pièces de tournage CNC en alliage d'aluminium

L'alliage d'aluminium est un matériau couramment utilisé pour les pièces de tournage CNC, offrant légèreté, haute résistance et une excellente résistance à la corrosion. Le tournage CNC peut produire des formes complexes et des pièces de haute précision à partir d'alliage d'aluminium. Ses avantages incluent une excellente dissipation thermique et une finition de surface, ce qui le rend largement utilisé dans les boîtiers électroniques, les supports de précision et divers composants structurels. De plus, la haute usinabilité de l'alliage d'aluminium permet une production efficace tout en maintenant une qualité constante.

Anodisation et anodisation dure

L'anodisation est souvent utilisée pour améliorer la résistance à l'usure et l'apparence des pièces tournées CNC en alliage d'aluminium. L'anodisation conventionnelle forme un film d'oxyde dense, résultant en une variété de couleurs et une surface esthétiquement agréable. L'anodisation dure, quant à elle, améliore encore la dureté et la résistance à la corrosion des pièces, ce qui la rend adaptée aux applications nécessitant un frottement élevé, des températures élevées et des environnements difficiles. Les deux procédés fournissent non seulement aux pièces une protection améliorée, mais prolongent également leur durée de vie.

Pièces de tournage CNC automobiles

Les pièces tournées CNC jouent un rôle clé dans l'industrie automobile. De nombreuses pièces de moteur, composants de transmission et connecteurs de précision reposent sur des processus de tournage de haute précision. Les pièces tournées CNC garantissent des performances stables sur de longues périodes de fonctionnement, améliorant efficacement la sécurité et la durabilité des véhicules. De plus, l'anodisation ou d'autres traitements de surface peuvent encore améliorer la résistance à la corrosion et la résistance mécanique, répondant aux exigences strictes de l'industrie automobile en matière de pièces de haute qualité.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!